As a senior project for her undergraduate degree, designer Sarah Roseman created a new kind of artform entirely: a fusion between glass and textile.

The Canadian designer spent almost a year researching innovative and sustainable alternatives for the glass industry. She also experimented with fiberglass (a material traditionally used as a composite with casted plastic for various applications) by melting it in the ultra-high heat of a kiln. As the glass reached a soft state, Roseman manipulated it into intricate shapes and patterns, including lattice, lace, and honeycombs.

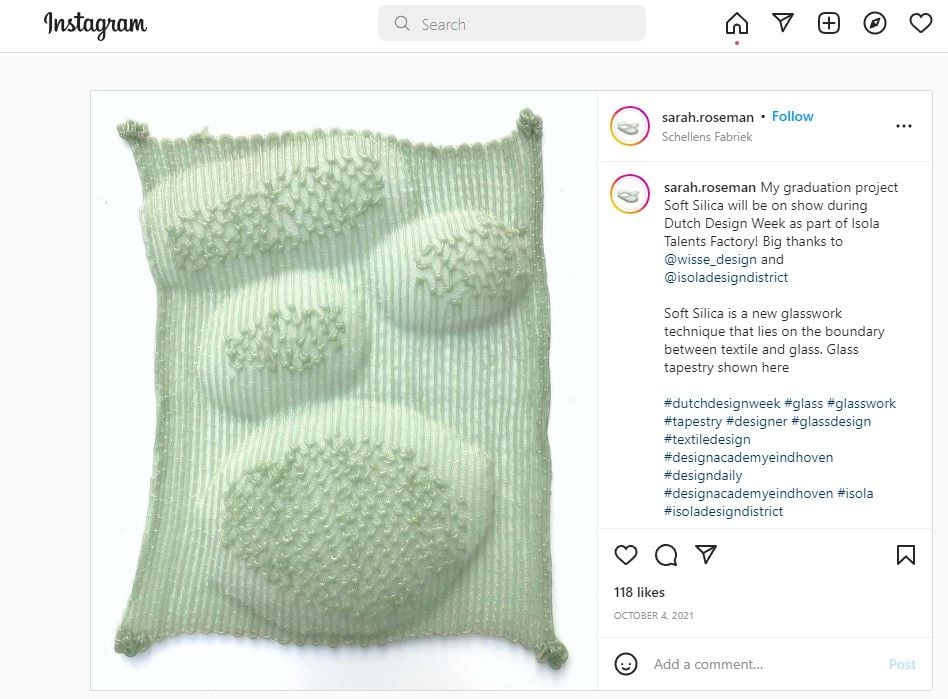

“The resulting material shows the movement of the melting of glass and carries surprising tactility that shows textile in a new way,” explains Roseman, a recent graduate of Design Academy Eindhoven in the Netherlands. “This glass work technique is a dialogue between the textile and the kiln, as both parts of the process can be adjusted in order to achieve different results.”

She played around with those techniques by letting the glass drip and slump in different positions before fusing pieces together.

“Glass is a dynamic material, and the technique of slumping allows delicate control over the movement of its molten state,” she adds. “The beauty of working with glass in this intricate way is the ability to see the melting material caught in midair, creating a material that can look like it is suspended in time.”

Submitting her project to , Roseman produced a collection of pieces, highlighting the many possible variations of her “Soft Silica” material. One twisted tube looks convincingly like it’s made of woven string and flexible , while another mimics the tiny pattern of medical gauze. Others are spaghetti-like layered masses and gloopy stacks of loops.

“The challenges lie in the dialogue between the knitting process and the kiln, as both influence the end result,” Roseman notes, adding that “throughout my research, I have learned to think from both perspectives to achieve optimal results.”

The artist’s translucent sage green tapestries and sculptural handiwork were one of 60 projects on display at last year’s Dutch Design Week as part of the Isola Talent Factory exhibit. The cutting-edge event offers a look at “the design of the future and the future of design” each year, with an emphasis on innovation, experiment, and cross-overs. New, young talent like Roseman is particularly sought after at Dutch Design Week.

One exciting application of Roseman’s soft silica is the ability to run copper wiring through the complex glass pieces while they’re still flexible, making it possible to turn the material into lamps or other electrically-powered items. Roseman successfully inserted fine wire into the glass at all sorts of angles and shapes.

“The electricity can run directly through the material to power multiple light sources, which opens up the possibility of creating intricate wiring systems integrated directly into an object,” she says. She intends to continue her experimentation with soft silica as she begins her career as a designer and materials researcher.

More of Roseman’s work can be found on her and .

The post first appeared on .